Pioneering Change

Precious Metal Recovery

The Royal Mint is taking the lead in innovative technologies in reclaiming precious metals, creating sustainable jewellery whilst protecting the world we live in for future generations.

"The most sustainable way you can buy any product is buying something that you know will last longer than you will and one whose very creation is a benefit to the planet."

Dominic Jones, Creative Director 886 by The Royal Mint

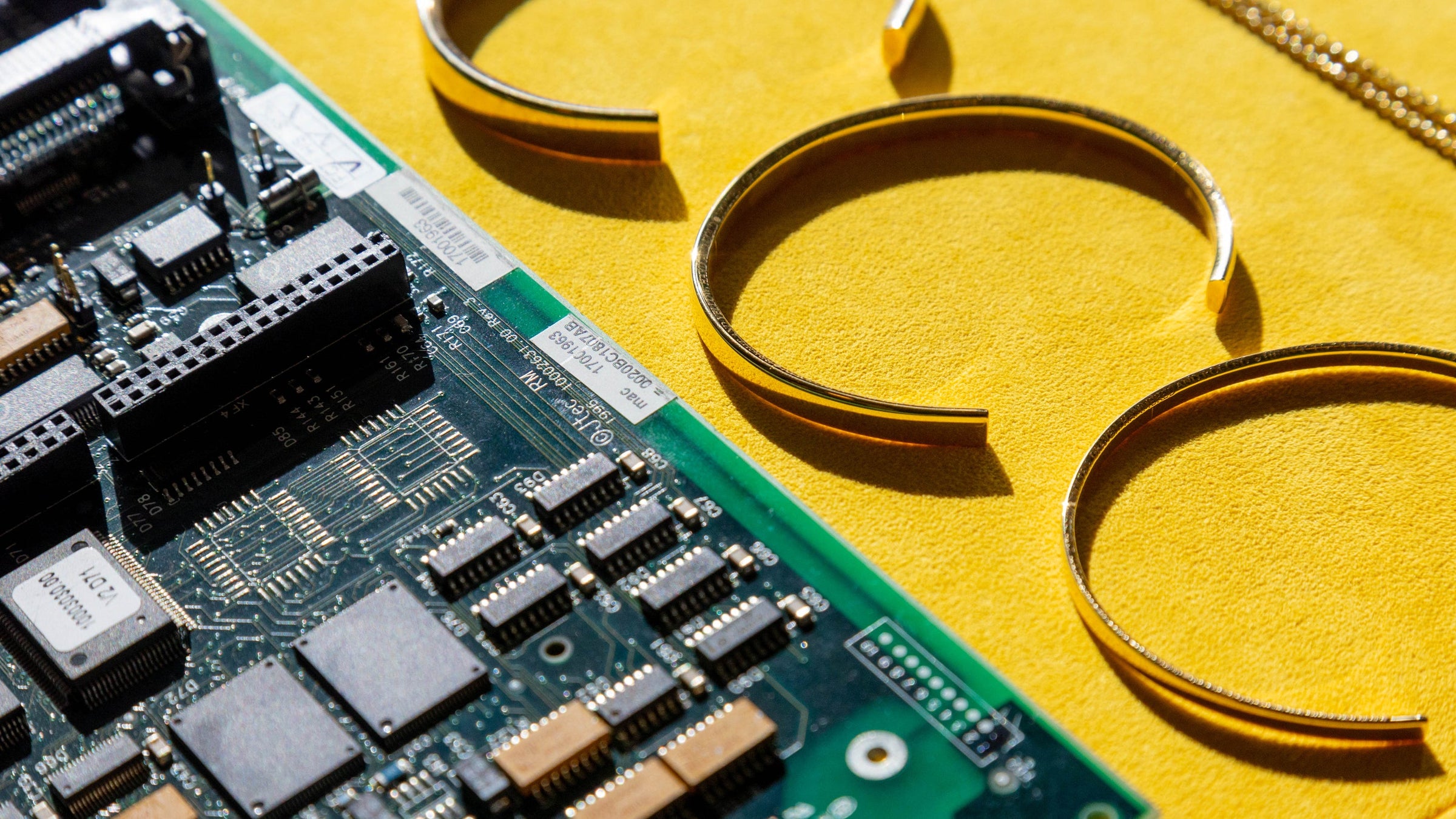

E-WASTE GOLD

Less than 20% of electronic waste is currently recycled world-wide and an estimated 7% of the world’s gold is locked-away in e-waste, along with other usable metals and materials.

This means that gold, silver, copper and other highly valued metals, valued at US $57 billion, are being discarded as opposed to being collected for treatment and reuse.

Our process provides a way to recover this gold – a finite, valuable material, as well as showcasing a more sustainable solution to the growing e-waste problem.

X-RAY SILVER

Pioneered by UK based company, Betts Metals Group, the x-ray silver is refined from the tonnes of segregated medical X-ray film from UK and Irish hospitals, stored at considerable cost to the healthcare provider; or sent to landfill, at considerable cost to the planet. Our partnership with Betts illustrates how we are willing to not only innovate ourselves, but partner with those that share the same values.

OUR MISSION

886 shares The Royal Mint’s sustainability ambitions to lead the way in the future of the jewellery and precious metals industry.

“We are transforming our business for the future – expanding into areas which complement our expertise in precious metals, champion sustainability, and support employment”.

- Anne Jessop, Chief Executive Officer at The Royal Mint